Services

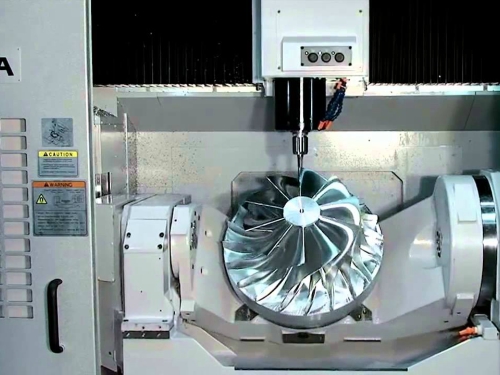

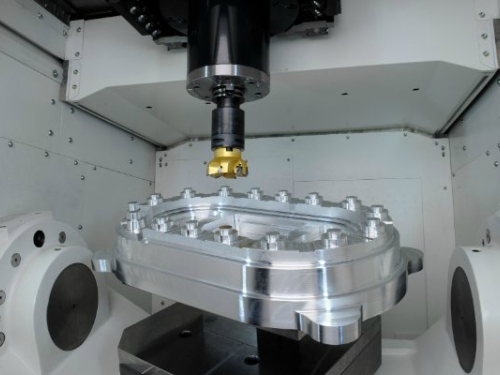

Machining services available in the workshop include:

Available at multiple locations:

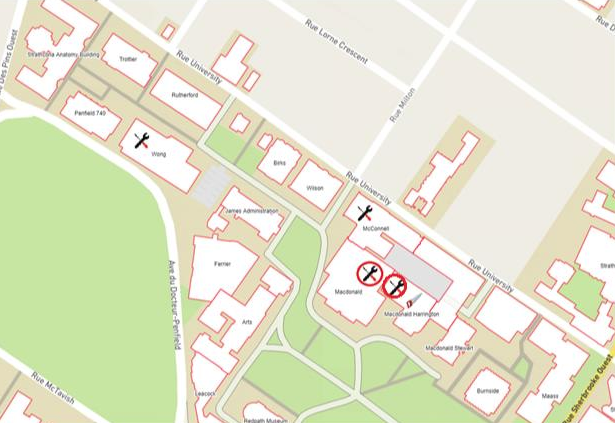

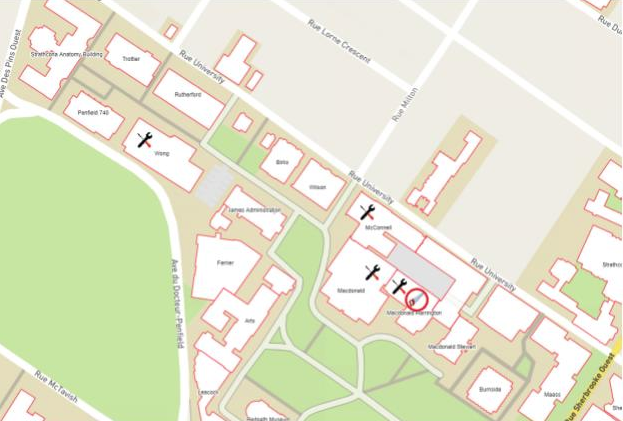

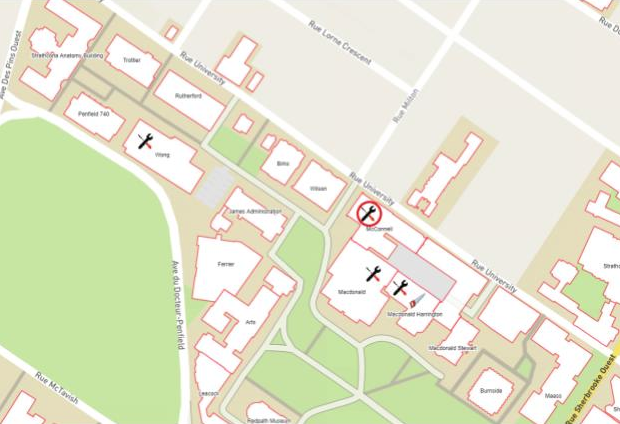

| Workshop | Contact Information | Opening Hour |

|---|---|---|

| ECE Design and Machining Workshop (ECE) | Room 607, McConnell Engineering Building (514) 398-7144 |

9:00 to 17:00, Monday to Friday |

| Machine Tool Lab (MTL) | Rooms 052, 056, 057 and 058, Macdonald Engineering Building (514) 398-6322, (514) 398-4375 |

9:00 to 17:00, Monday to Friday |

| Wong Machine Shop (Wong) | Room 3260, Wong Building (514) 398-4490 |

9:00 to 17:00, Monday to Friday |

| Students’ General Working Area (SGWA) | MD 051, Macdonald Engineering Building/B15, Macdonald-Harrington Engineering Building (514) 398-6322 |

24/7 |

| Architecture Wood Workshop | Rooms G14 & G25, Macdonald-Harrington Engineering Building (514) 398-6729 |

9:00 to 17:00, Monday to Friday |

Services available at each location is summarized as follows. For more details and work order download, please also refer to Workshop Rates/Policies.

| Services | ECE | MTL | Wong | SGWA |

|---|---|---|---|---|

| Drill Press | ||||

| Surface/Rotary/Wheel Grinders | ||||

| Lapping and Honing | ||||

| Lathe | ||||

| Milling | ||||

| Band Saws | ||||

| Fabricating and Sheet Metal Machines | ||||

| Welding/Soldering | ||||

| CNC Milling | ||||

| CNC Lathe | ||||

| CNC Router | ||||

| Coordinate Measuring Machines, CMM | ||||

| Rapid Prototyping | ||||

| Sand Plaster | ||||

| Painting Booth | ||||

| Carbon Fibre Booth |